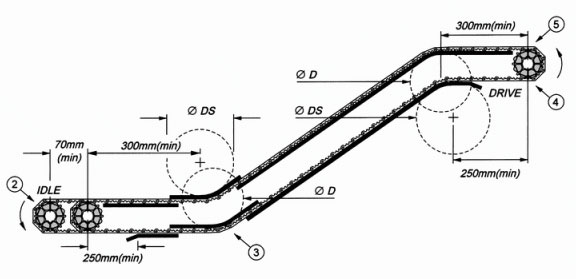

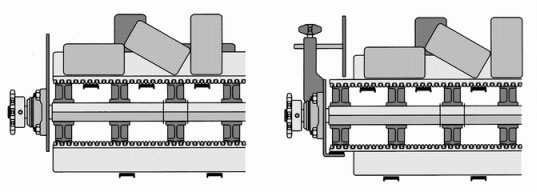

Swanneck conveyor

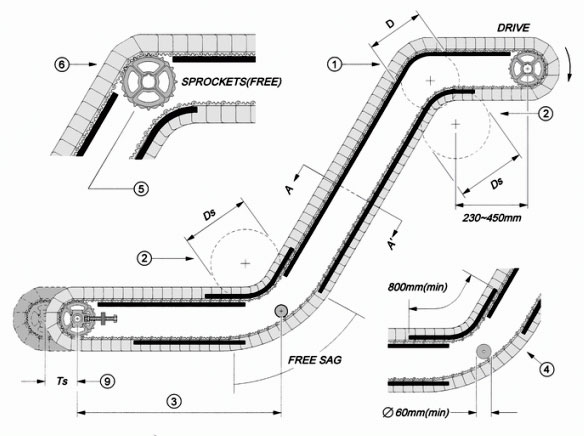

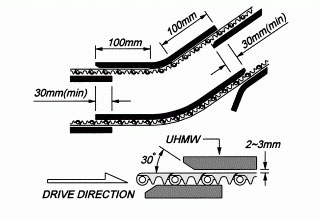

Hanyar goyan baya don lanƙwasa matsayi na mai ɗaukar hoto yana iya amfani da filayen filastik tare da ƙananan juzu'i, kamar UHMW, HDPE, da Acetal, don zama goyon baya na ƙasa.Don mafi ƙarancin diamita mai lanƙwasa, da fatan za a duba ƙayyadaddun ƙimar D&Ds.

Radius na baya shine matsananciyar tashin hankali;da fatan za a yi amfani da igiyoyin filastik tare da ƙananan juzu'i, kamar UHMW, HDPE, da Acetal don kera shi.Don mafi ƙarancin diamita mai lanƙwasa, da fatan za a duba ƙayyadaddun ƙimar D&Ds.

Matsayin tuƙi a hanyar dawowa na swanneck mai isar da isar da sako kuma nau'in radius ne na baya;wani sako-sako da tashin hankali ne.Ana iya ƙila za a ƙirƙira shi da rollers ko filayen filastik tare da ƙananan juzu'i don tallafawa.

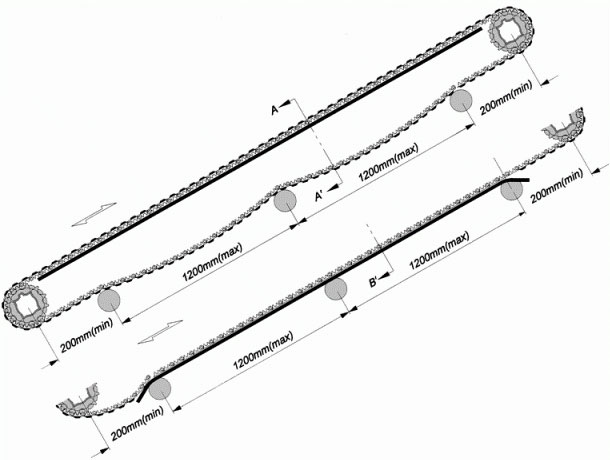

Idan tsayin kwance tsakanin sprocket mara aiki da matsayi mai lankwasa ya wuce 900mm, da fatan za a shigar da maƙallan a kasan hanyar dawowa.

Lokacin da catenary sag yana bayyana a cikin hanyar dawowar mai jigilar swanneck kuma saurin aiki bai wuce 20M/min ba, ana iya yin watsi da shi kuma a bar shi ya ragu cikin yardar kaina.Koyaya, idan saurin ya wuce 20M/min, dole ne a saita abin nadi tare da diamita sama da 60mm don rage yanayin tsalle wanda ya samo asali daga sag na bel na jigilar kaya.

Lokacin ɗaukar sprocket na Hongsbelt ya zama hanyar tallafi na kusurwa mai lankwasa kuma saurin aiki ya wuce 15m / min, yakamata a yi amfani da sprocket tare da hakora sama da 12, amma don Allah gyara duk sprockets tare da zoben riƙewa kuma cire farantin jagora daga sprocket.

Wajibi ne a ƙirƙira tare da matsi rollers ko tube a kan swanneck karkata conveyors.Matsakaicin madaurin tsiri ba zai iya zama ƙasa da 100mm ba kuma dole ne ya saita madaidaicin tashin hankali a wuri mara aiki don samun tashin hankali da ya dace.

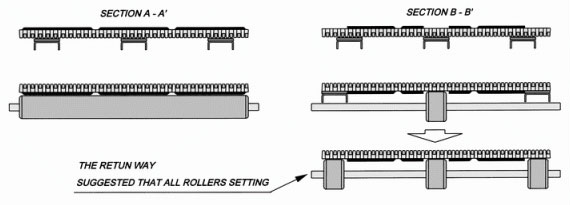

Sashe na A-A' Ƙayyadaddun Ƙira

Mai Canzawa

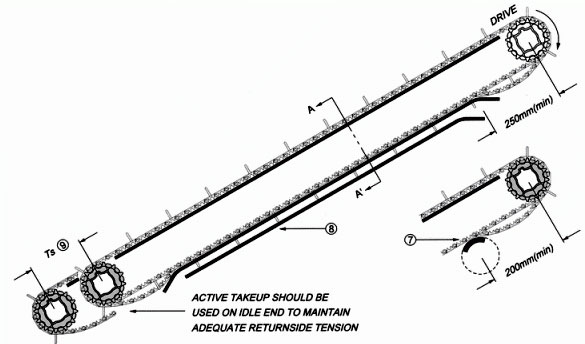

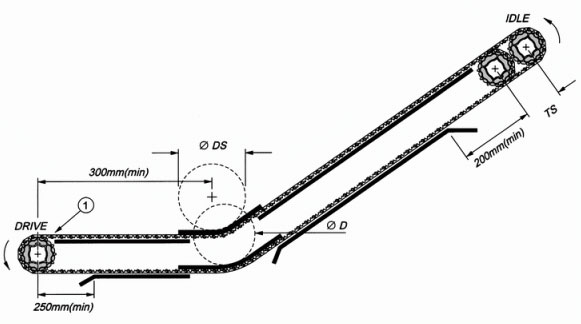

Idan hanyar tuƙi na isar da isar da isar da sako shine babban tuƙi, wurin tuntuɓar tsakanin cibiyar sprocket ɗin tuƙi da nadi na farko ko wearstrip a hanyar dawowa dole ne ya kiyaye tazarar sama da 200mm don barin bel ɗin ya sami isasshen sararin samaniya kuma a guje masa samun sabon haɗin gwiwa tare da sprockets. kuma yana haifar da rudani.Da fatan za a duba matsayi na 7 na hoton da ke sama.

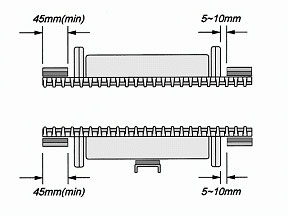

Idan nisa na bel ɗin ya fi 600mm, ya kamata a shigar da kayan aikin taimako na tsakiya a saman jirgin a hanyar dawowa.Da fatan za a koma zuwa Sashe A - A' kuma duba matsayi na 8 na hoton da ke sama.

TS shine daidaitawar tashin hankali;don tsarin daidaita tazara, da fatan za a koma zuwa babin Tsawon Belt & Tension.Da fatan za a duba matsayi na 9 na hoton da ke sama.

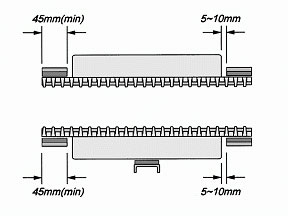

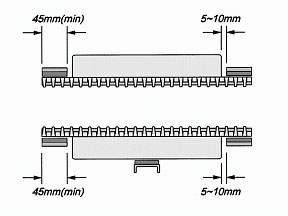

Sashe na A-A' Ƙayyadaddun Ƙira

Rubuta EL

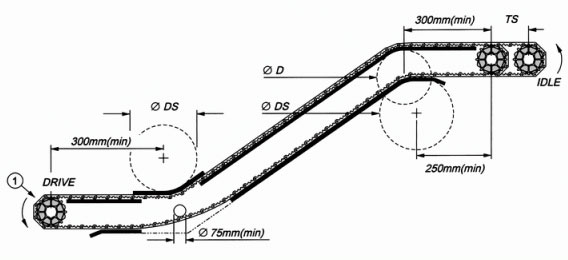

Tazarar da ke tsakanin sprocket na tuƙi/mai aiki da wurin tuntuɓar farko ta hanyar dawowa, komai abin abin nadi ko wearstrip, dole ne a kiyaye fiye da 200mm.

Matsakaicin tazara tsakanin duk masu goyan baya a hanyar dawowa baya wuce 1.2M.

Don sauran wuraren ƙira, da fatan za a koma zuwa Swanneck Conveyor da hoton da ke ƙasa.

Domin Series 200 EL da Series 300HDEL, an sarrafa su da manna TPE guda a kan PP abu bel.TPE babban matakin kariya ne;aikace-aikacen da aka fi amfani da shi shine abin hana buroshin hakori.Ana iya sake yin fa'ida ba tare da wata damuwa game da kariyar muhalli ba, kuma a haɗe tare da kayan PP don zama ƙari wanda zai iya ƙarfafa ƙarfin hali.Ba tare da la'akari da karkata ko raguwa ba, kusurwar karkata ba zai iya wuce 40 ° ba.

Ƙayyadaddun Ƙira na Sashe

Matsakaicin diamita na abin nadi hanyar dawowa baya iya kasa da 600mm.Yana iya amfani da rollers a hanyar dawowa a cikin dukan tafiya;duk da haka, gudun ya kamata ya kasance a cikin 30M / min kuma ya kamata a sarrafa catenary sag a cikin 35mm don kauce wa TPE flange mai ɗaukar nauyin rollers tare da babban kusurwa kuma ya haifar da mummunan aiki.

Hakanan zai iya ɗaukar hanyar ƙira kamar yadda kwatancin, sashe B-B', ya nuna a sama.Don kwatancin da ke sama, ɗorawa suna goyan bayan ɓangarorin biyu kuma ana goyan bayan abin nadi a tsakiya.Don misalin da ke ƙasa, ya ɗauki rollers don tallafawa cikin sassa uku.Dukansu biyu sune hanya mafi kyau don ƙira.

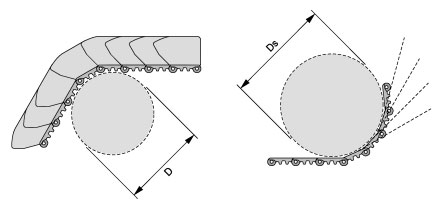

Backbend Radius DS

Dukkanin samfuran jigilar belt na HONGSBELT an haɗe su zuwa rukunin da aka kulle, yana da mafi ƙarancin iyakancewar radius;sabili da haka, don sanya bel ɗin ya wuce ta yankin baya a hankali, da fatan za a kula da iyakance mafi ƙarancin diamita lokacin zayyana mai jigilar kaya kuma koma zuwa teburin da ke ƙasa don gyara radius na kowane jerin).

HONGSBELT bel mai ɗaukar nauyi yana da ikon yin aiki a cikin ƙira mai isarwa;m yana samuwa don isa kowane kusurwa mai karkata tare da daidaitaccen lissafin diamita na radius na baya.

guda: mm

| Jerin | 100 A | 100 B | 200 A | 200 B | 300 | 400 | 500 | 501B | 502A/B | |

| D | Ba tare da Side Guard ba | 250 | 250 | 135 | 120 | 200 | 45 | 150 | 150 | 180 |

| Tare da Side Guard | 250 | 250 | 135 | 120 | 200 | -- | -- | 180 | 200 | |

| DS | Ba tare da Side Guard ba | 250 | 200 | 150 | 120 | 220 | 45 | 150 | 180 | 200 |

| Tare da Side Guard | 280 | 230 | 300 | 290 | -- | -- | -- | 200 | 230 | |

Bayanin Radius na baya

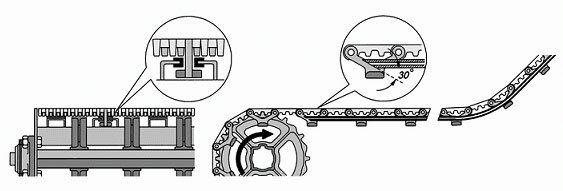

Radius na baya na tsarin isar da isar da sako tsari ne na gama gari don cimma manufar isar da niyya.Sabili da haka, wajibi ne a yi la'akari da motsi mai laushi na saman bel ko ƙasa yayin zayyana wurin riƙe ƙasa.Da fatan za a koma ga hoton da ke sama.Dangane da kayan da ya dace don tuntuɓar da sawa tare da bel, muna ba da shawarar ɗaukar kayan HDPE ko UHNW lokacin da saurin ya gaza 20 M/min;idan gudun ya fi 20 M/min, da fatan za a ɗauki kayan UHMW ko TEFLON.

Da fatan za a sarrafa ko niƙa wurin riƙe ƙasa zuwa ƙwanƙwasa digiri 30 a ƙofar don tabbatar da mai ɗaukar hoto tare da motsi mai santsi.

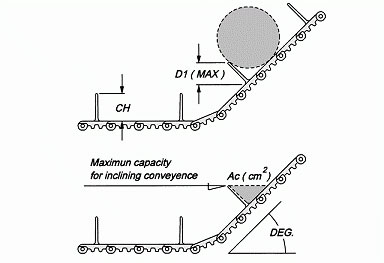

Angle & iyawa

Idan ƙarfin jigilar kaya ya yi girma da yawa, don guje wa abubuwan da ke faɗowa daga hanyar jigilar kaya, bai dace a ɗauki ƙananan masu gadi na gefe ba ko ƙira tare da babban gradient a cikin mai ɗaukar nauyi.Da fatan za a ba da kulawa ta musamman ga alaƙar dangi tsakanin ƙarfin kaya da kusurwar karkata, kuma koma ga hoton da ke ƙasa.

Naúrar: CH = mm, D1 = mm, Ac = cm2

| DEG. | 15° | 20° | 25° | 30° | 35° | 40° | 45° | 50° | ||

| CH | 25 | D1 | 23 | 22 | 21 | 20 | 19 | 17 | 16 | 15 |

| Ac | 11 | 8 | 6 | 5 | 4 | 3 | 3 | 2 | ||

| 50 | D1 | 46 | 45 | 46 | 40 | 38 | 35 | 32 | 29 | |

| Ac | 46 | 34 | 26 | 21 | 17 | 14 | 12 | 10 | ||

| 75 | D1 | 70 | 67 | 64 | 61 | 57 | 53 | 48 | 42 | |

| Ac | 104 | 77 | 60 | 48 | 40 | 33 | 27 | 23 | ||

| 100 | D1 | 9. | 90 | 86 | 81 | 76 | 70 | 64 | 57 | |

| Ac | 186 | 137 | 107 | 86 | 71 | 60 | 50 | 41 | ||

| 125 | D1 | 117 | 113 | 108 | 102 | 95 | 88 | 80 | 71 | |

| Ac | 291 | 214 | 167 | 136 | 111 | 92 | 77 | 65 | ||

| 150 | D1 | 140 | 136 | 129 | 122 | 114 | 106 | 96 | 86 | |

| Ac | 490 | 360 | 281 | 227 | 186 | 156 | 130 | 109 | ||

Don sakamakon iyawar lodi, da fatan za a ninka darajar Ac tare da ingantacciyar faɗin (cm) na jirgin .

Ƙarƙashin Mai Canjawa

Gabaɗaya, don ƙira tsarin isar da iskar gas, mun ba da shawarar amfani da nau'in A ko nau'in B azaman misalin isarwa.an tsara tsarin jigilar kaya don tuƙi a ƙasan mai ɗaukar kaya kamar yadda matsayi na 1 na hoton da ke ƙasa ya nuna.Don ƙimar D & DS, da fatan za a koma zuwa Radius Ds na baya a menu na hagu.

Nau'in B

Idan ya zama dole a ɗauki nau'in C a matsayin misalin ƙira na isarwa, daidaita tazarar Ts yakamata a kiyaye aƙalla 75mm.Don ƙimar D & DS, da fatan za a koma zuwa Radius Ds na baya a menu na hagu.

Nau'in C

Matsayin da ya dace na matsayi 3 yakamata ya karɓa daga daidaitawar tashin hankali na matsayi 2.

Domin yin backend radius a matsayi 4 da kasa na drive sprocket sami mafi m kwana kwana da kuma dace tashin hankali, da kuma amfana da aiki na bel, shi wajibi ne don daidaita tashin hankali a matsayi 2 da kuma riƙe ƙasa a matsayi 3.

Idan ba zai iya karɓar tashin hankali da ya dace ta wurin matsayi na 2 ba, zai haifar da sakamakon riƙewa ba zai iya karɓa daga matsayi na 3 da 4. Wannan na iya haifar da tashin hankali na bel tazara wanda zai haifar da kusurwar nadawa a matsayi na 5. Sprocket ɗin zai sami haɗin kai mara kyau kuma zai haifar da tsayawa da kasawa.

Nau'in D

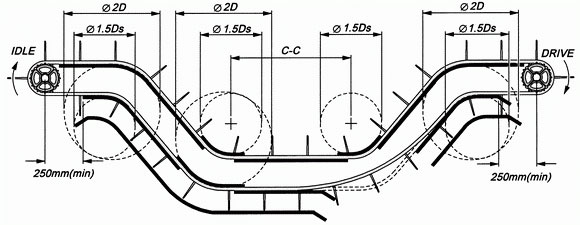

Multi Backend Radius

Don ƙirar radius na baya da yawa, ya kamata a sanya suturar a kan hanyar dawowa don tallafawa saman jirgin, don guje wa lalata bel ko rugujewa da firam ɗin jigilar kaya.Da fatan za a duba hoton da ke ƙasa.

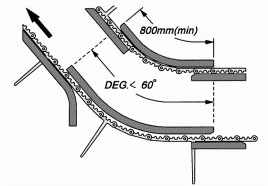

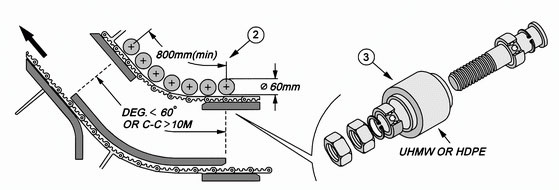

Idan kusurwar lanƙwasawa ta ƙasa da digiri 60, zai iya amfani da dogo mai riƙewa da aka yi da filastik injiniyan UHMW don riƙe ƙasa biyu na ƙarshen ƙarshen bel.Don yin la'akari da ƙimar D & DS don Allah duba tebur mai zuwa a ƙarshen wannan shafin da ke ƙasa.)

Idan kusurwar karkata ya fi digiri 60, muna ba da shawarar yin amfani da abin nadi mai tuƙi zuwa matsayi a ƙarƙashin bel, don rage yankin abrasion da rage tashin hankali na dawowa.

Ya kamata a gina salon rikitar da abin nadi ta hanyar daidaitaccen tsari, dole ne ya ƙara ɗora kafafe akan kusurwar karfen firam ɗin jigilar kaya ta hanyar dunƙule goyan bayan kamar yadda aka nuna a sama.(Don ma'anar darajar D & DS don Allah duba tebur mai zuwa a ƙarshen wannan shafin da ke ƙasa.)

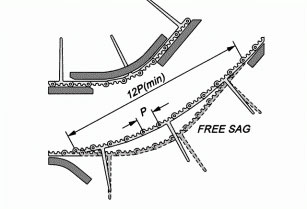

Nisa na dawowa hanyar catenary sag an ba da shawarar a adana aƙalla faɗin module guda 12, domin samun hanyar dawowa samun isasshen sarari don sakin tashin hankali.

Bayanan kula

HONGSBELT modular bel ya dace sosai don amfani a kowane nau'in yanayin yanayin zafi mai zafi, kamar tururi da ruwan zafi da aka nutsar da su da dai sauransu Lokacin ɗaukar bel ɗin HONGSBELT a cikin yanayin zafin jiki, da fatan za a yi amfani da sandunan bakin karfe da hanyoyin haɗin ƙarfe don shawo kan abin da ya haifar da ɓarna. radius na baya.Muna da ƙwarewa da yawa a aikace-aikacen zafin jiki mai girma, kuma muna shirye mu yi muku hidima.Don abubuwan da suka danganci zayyana tsarin jigilar kaya, zaku iya yin shawarwari tare da mu koyaushe.

Riƙe Moduloli

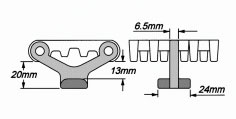

Mai isar da isar da saƙo zai iya dakatar da riƙon kayayyaki (HDM), na'ura ce mai jagora musamman wacce aka ƙera don radius na baya akan hanyar dawowar.Riƙe ƙananan kayayyaki suna cikin ƙirar T, kuma an shigar dasu a ƙarƙashin bel ɗin, don riƙe bel ɗin.Zai iya kaiwa sakamakon karkata ba tare da riƙe matsayin radius na baya ba, kuma kar a ɗauki rollers don tallafawa bel akan hanyar dawowa.

Bayanin Shigar HDM

Lokacin shigar da HDM, da fatan za a ɗauki ƙananan kayan haɗin gwal kamar UHMW ko HDPE a wurin tuntuɓar.Kada ka bari HDM ta tuntuɓar kayan ƙarfe kai tsaye.Yana iya lalata bel ɗin jigilar kaya saboda gogayya.Domin , Gudanar da wearstrip a ƙofar zuwa 30 digiri chamfer don samun ingantaccen aiki na HDM.Da fatan za a koma ga hoton da ke sama.

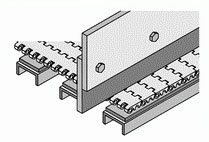

Rigakafin gefe

HONGSBELT na'ura mai ɗaukar hoto na zamani kuma na iya haɗawa tare da kafaffen masu gadi na gefe don hana samfuran faɗuwa daga gefen bel.Yakamata a yi amfani da kayan filastik mai girma na injiniya don gina abin da aka makala a gefe, kuma dole ne a adana tazarar aminci tsakanin bel da kafaffen nau'in gadin gefen.Haka kuma, ya zama dole a guji amfani da abubuwa masu laushi irin su PVC, PU ko kayan saƙar fiber don shafa saman bel ɗin kai tsaye, yana iya haifar da lalacewa ga saman bel ɗin.Da fatan za a koma ga hoton da ke ƙasa.

Babban Kuma Mara Gurbatawa Samfura

Aikace-aikacen da ke sama gabaɗaya don babu gurɓatawa ko isar da samfuran girma masu girma.Wannan misalin ƙira an ƙara shi babban tsarin na'urar kai tsaye, don samar da aikin azaman masu tsaro na gefe.

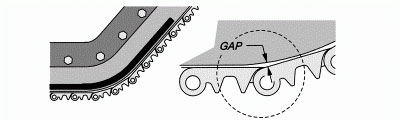

Bayanan kula don Lankwasawa Belt Gap

Tsarin samfuran HONGSBELT shine naúrar kulle-kulle.Sabili da haka, duk yadda matakan kariya na gefe suke da tsauri, ratar triangular zai ci gaba da bayyana akan wurin lanƙwasa bel.Da fatan za a koma ga hoton da ke sama.Dole ne a lura da shi yayin ƙira ko la'akari don ɗaukar kayan haɗin HONGSBELT, masu gadin gefe.Bugu da kari, abu kamar HDPE ko UHMW warp, gezaren jakar filastik, ragowar kayan filastik ko wani lebur da kankanin abu na iya yuwuwa shiga cikin ratar bel ko ramin.

Wadannan abubuwa na waje na iya haifar da na'ura zuwa matsa lamba ko tsoma bakin jujjuyawar bel, idan ba a la'akari da haɗe tare da gadin gefen HONGSBELT don rigakafin faɗuwar gefe ba, muna ba da shawarar mafi ƙarancin kauri na kayan jigilar kayayyaki dole ne aƙalla girman ninki biyu fiye da gibin triangular bel.

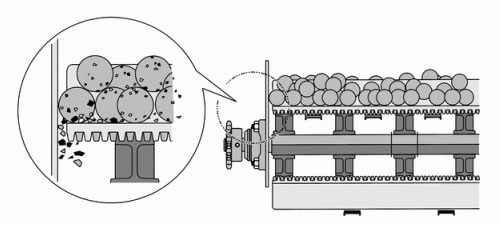

Ƙananan Barbashi

Ƙananan abubuwa da kayan gurɓataccen sauƙi kamar biskit, busassun 'ya'yan itace, da fodder suna da sauƙin faɗuwa daga saman bel.Ƙananan barbashi na waɗannan kayan za su taru a kan tsarin jigilar kaya, kuma su faɗo cikin kuncin bel ɗin jigilar kaya.Don hana ƙaramin abu ya shiga cikin bel da tsarin jigilar kaya, muna ba ku shawarar tsara na'urar jigilar ku kamar yadda aka kwatanta a ƙasa;zai sami mafi kyawun kariya ga kayan aiki.