Juya Raka'a

| Turanci (Amurka) Unit X | A ninka ta | = Nau'in awo | X ninka ta | = Turanci (Amurka). | ||

| Ma'aunin Layi | in | 25.40 | mm | 0.0394 | in | Ma'aunin Layi |

| in | 0.0254 | m | 39.37 | in | ||

| ft | 304.8 | mm | 0.0033 | ft | ||

| ft | 0.3048 | m | 3.281 | ft | ||

| Ma'auni | in2 | 645.2 | mm2 | 0.00155 | in2 | Ma'auni |

| in2 | 0.000645 | m2 | 1550.0 | in2 | ||

| ft2 | 92.903 | mm2 | 0.00001 | ft2 | ||

| ft2 | 0.0929 | m2 | 10.764 | ft2 | ||

| Ma'aunin Cubic | ft3 | 0.0283 | m3 | 35.31 | ft3 | Ma'aunin Cubic |

| ft3 | 28.32 | L | 0.0353 | ft3 | ||

| Yawan Gudu | ft / s | 18.29 | m / min | 0.0547 | ft / s | Yawan Gudu |

| ft / min | 0.3048 | m / min | 3.281 | ft / min | ||

| Avoirdupois Nauyi | lb | 0.4536 | kg | 2.205 | lb | Avoirdupois Nauyi |

| lb/ft3 | 16.02 | kg/m3 | 0.0624 | lb/ft3 | ||

| Ƙarfin Ƙarfafawa | lb | 0.4536 | kg | 2.205 | lb | Ƙarfin Ƙarfafawa |

| lb | 4.448 | Newton (N) | 0.225 | lb | ||

| kg | 9.807 | Newton (N) | 0.102 | kg | ||

| lb/ft | 1.488 | kg / m | 0.672 | lb/ft | ||

| lb/ft | 14.59 | N/m | 0.0685 | lb/ft | ||

| kg - m | 9.807 | N/m | 0.102 | kg - m | ||

| Torque | ina - lb | 11.52 | kg - mm | 0.0868 | ina - lb | Torque |

| ina - lb | 0.113 | N - m | 8.85 | ina - lb | ||

| kg - mm | 9.81 | N - mm | 0.102 | kg - mm | ||

| Juyawa Inertia | in4 | 416.231 | mm4 | 0.0000024 | in4 | Juyawa Inertia |

| in4 | 41.62 | cm4 | 0.024 | in4 | ||

| Matsi / Damuwa | lb / in2 | 0.0007 | kg / mm2 | 1422 | lb / in2 | Matsi / Damuwa |

| lb / in2 | 0.0703 | kg / cm2 | 14.22 | lb / in2 | ||

| lb / in2 | 0.00689 | N/mm2 | 145.0 | lb / in2 | ||

| lb / in2 | 0.689 | N/cm2 | 1.450 | lb / in2 | ||

| lb/ft2 | 4.882 | kg/m2 | 0.205 | lb/ft2 | ||

| lb/ft2 | 47.88 | N/m2 | 0.0209 | lb/ft2 | ||

| Ƙarfi | HP | 745.7 | wata | 0.00134 | HP | Ƙarfi |

| ft - lb / min | 0.0226 | wata | 44.25 | ft - lb / min | ||

| Zazzabi | °F | TC = (°F - 32) / 1.8 | Zazzabi | |||

Bayani na BDEF

| Alama | Naúrar | |

| BS | Isar da bel mai ƙarfi | Kg/M |

| BW | Nisa Belt | M |

Ma'anar Alamar C

| Alama | Naúrar | |

| Ca | Duba Table FC | ---- |

| Cb | Duba Table FC | ---- |

D Ma'anar Alamar

| Alama | Naúrar | |

| DS | Ragowar Shaft | mm |

E Ma'anar Alamar

| Alama | Naúrar | |

| E | Rate Tsawaita Shaft | Gpa |

F Ma'anar Alamar

| Alama | Naúrar | |

| FC | Ƙwaƙwalwar juzu'i Tsakanin Belt Edge da Riƙe Tashi | ---- |

| FBP | Rassawa mafi inganci ta hanyar ɗaukar samfurin da bel ɗin | ---- |

| FBW | Ƙimar Ƙarfafawa na Kayan Tallafi na Belt | ---- |

| FA | Ƙimar Ƙimar Ƙimar Ƙimar | ---- |

| FS | Ƙarfin Ƙarfin Ƙarfin Ƙarfafawa | ---- |

| FT | Canza belt Temperature Coefficient Coefficient | --- |

Alamar HILM

| Alama | Naúrar | |

| H | Matsayin Mai Canjawa karkata tsayi. | m |

| HP | Ƙarfin doki | HP |

I Ma'anar Alamar

| Alama | Naúrar | |

| I | Lokacin Inertia | mm4 |

L Alamar Ma'anar

| Alama | Naúrar | |

| L | Nisan Isarwa (Tsarin Wuta Daga Shafar Tuba Zuwa Shafar Idler) | M |

| LR | Komawa Tsawon Sashe Madaidaicin Gudu | M |

| LP | Tsawon Sashe na Tsawon Hanya madaidaiciya | M |

M Ma'anar Alamar

| Alama | Naúrar | |

| M | Karkace Matsayin Mai Canja wurin | ---- |

| MHP | Horsepower | HP |

Bayani na PRS

| Alama | Naúrar | |

| PP | Kashi Kashi na Ma'auni na Ma'auni na Samfur na Hanyar ɗauka | ---- |

Ma'anar Alamar R

| Alama | Naúrar | |

| R | Sprocket Radius | mm |

| RO | Waje Radius | mm |

| rpm | Juyin Juya Halin Minti | rpm |

Ma'anar Alamar S

| Alama | Naúrar | |

| SB | Tsakanin Tazara | mm |

| SL | Jimlar Loading Shaft | Kg |

| SW | Nauyin Shaft | Kg/M |

Alamar TVW

| Alama | Naúrar | |

| TA | Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfafawa | Kg/M |

| TB | Ka'idar Ka'idar Conveyor Belt | Kg/M |

| TL | Tashin hankali na Sag na Rukunin Conveyor Belt Unit Catenary. | Kg/M |

| TN | Tashin hankali Na Sashe | kg/M |

| TS | Torque | Kg.mm |

| TW | Jumlar Tashin Hankali Mai ɗaukar belt | Kg/M |

| TWS | Musamman Nau'in Mai ɗaukar Belt Unit Jimlar tashin hankali | Kg/M |

V Ma'anar Alamar

| Alama | Naúrar | |

| V | Gudun Isarwa | M/min |

| VS | Gudun Ka'idar | M/min |

Ma'anar Alamar W

| Alama | Naúrar | |

| WB | Nauyin Nauyin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Kg/M2 |

| Wf | Matsakaicin Matsala Mai Taruwa | Kg/M2 |

| WP | Nauyin Nauyin Nau'in Nauyin Samfurin belt |

|

Pusher da Bidirectional

Ga mai turawa ko isar da saƙon bidirectional, ƙarfin bel ɗin zai kasance sama da na yau da kullun a kwance;sabili da haka, igiyoyi a ƙarshen biyu ya zama dole a yi la'akari da su azaman tuƙi kuma an ƙaddamar da su a cikin lissafi.Gabaɗaya, yana da kusan sau 2.2 na abubuwan ƙwarewa don samun jimlar bel ɗin tashin hankali.

FORMULA: TWS = 2.2 TW = 2.2 TB X FA

TWS a cikin wannan naúrar yana nufin lissafin tashin hankali na mai kai bidirectional ko turawa.

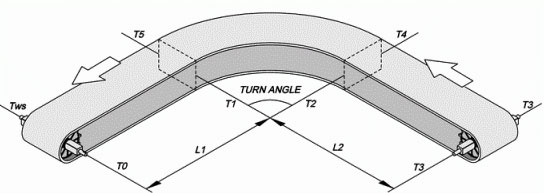

Juya lissafin

Lissafin tashin hankali TWS na mai juyawa shine don ƙididdige tashin hankali da aka tara.Sabili da haka, tashin hankali a cikin kowane sashi mai ɗaukar nauyi zai shafi ƙimar jimlar tashin hankali.Wannan yana nufin, jimlar tashin hankali yana tarawa daga farkon sashin tuƙi ta hanyar dawowa, tare da hanyar dawowa zuwa sashin mara amfani, sannan ta wuce sashin ɗaukar hoto zuwa sashin tuƙi.

Wurin ƙira a cikin wannan rukunin shine T0 wanda ke ƙarƙashin mashin tuƙi.Darajar T0 daidai yake da sifili;muna lissafin kowane sashe daga T0.Misali, sashin farko madaidaiciya a hanyar dawowa shine daga T0 zuwa T1, kuma wannan yana nufin tarin tashin hankali na T1.

T2 shine tashin hankali da aka tara na matsayi na juyawa a hanyar dawowa;a wata kalma, shine tarin tashin hankali na T0, T1 da T2.Da fatan za a yi la'akari da misalin da ke sama kuma ku gano tarin tashin hankali na sassan ƙarshe.

FORMULA: TWS = (T6)

Jimlar tashin hankali na sashin tuƙi a cikin hanyar ɗauka.

TWS a cikin wannan rukunin yana nufin lissafin tashin hankali na mai juyawa.

FORMULA: T0 = 0

T1 = WB + FBW X LR X WB

Tashin hankali na catenary sag a wurin tuƙi.

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X WB

Tashin hankali na sashin juyawa a hanyar dawowa.

Don ƙimar Ca da Cb, da fatan za a koma zuwa Table Fc.

T2 = ( Ca X T2-1 ) + ( Cb X FBW X RO ) X WB

TN = ( Ca X T1 ) + ( Cb X FBW X RO ) X WB

FORMULA: TN = TN-1 + FBW X LR X WB

Tashin hankali na sashin madaidaiciya a hanyar dawowa.

T3 = T3-1 + FBW X LR X WB

T3 = T2 + FBW X LR X WB

FORMULA: TN = TN-1 + FBW X LP X ( WB + WP )

Tashin hankali na sashin madaidaiciya a cikin hanyar ɗauka.

T4 = T4-1 + FBW X LP X ( WB + WP )

T4 = T3 + FBW X LP X ( WB + WP )

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

Tashin hankali na sashin juyawa a cikin hanyar ɗauka.

Don ƙimar Ca da Cb, da fatan za a koma zuwa Table Fc.

T5 = ( Ca X T5-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

T5 = ( Ca X T4 ) + ( Cb X FBW X RO ) X ( WB + WP )

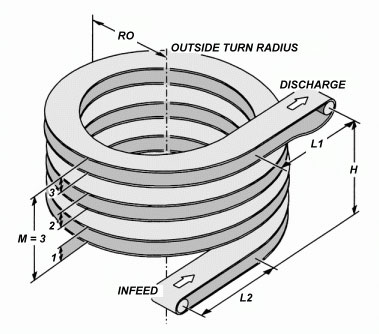

Karkace Mai Canjawa

FORMULA: TWS = TB × FA

TWS a cikin wannan naúrar yana nufin lissafin tashin hankali na mai ɗaukar hoto.

FORMULA: TB = [ 2 × RO × M + ( L1 + L2 ) ] ( WP + 2WB ) × FBW + ( WP × H )

FORMULA: TA = BS × FS × FT

Da fatan za a koma zuwa Table FT da Table FS.

Misali Mai Aiki

Kwatankwacin TA da tarin fuka, da sauran lissafin da ke da alaƙa iri ɗaya ne da sauran nau'ikan jigilar kaya.Akwai wasu ƙuntatawa da ƙa'idodi akan ƙira da ginin mai jigilar karkace.Don haka, yayin da ake amfani da HONGSBELT karkace ko juya bel zuwa tsarin jigilar kaya, muna ba ku shawarar ku koma zuwa littafin Injiniya na HONGSBELT da tuntuɓar sashen sabis na fasaha don ƙarin bayani da cikakkun bayanai.

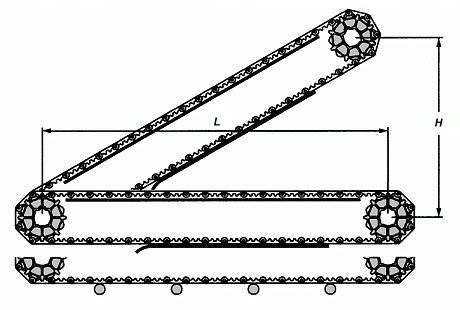

Tashin hankali

FORMULA: TB = [ ( WP + 2WB ) X FBW ] XL + ( WP XH )

Idan ɗaukar samfuran suna tare da halayen tarawa, ƙarfin juzu'i na Wf wanda ke ƙaruwa yayin jigilar jigilar kaya yakamata ya kasance ƙarƙashin lissafi.

FORMULA: TB = [ ( WP + 2WB ) X FBW + Wf ] XL + ( WP XH )

FORMULA: Wf = WP X FBP X PP

Tashin Hankali

Saboda nau'in nau'i na bel yana da ƙarfi daban-daban wanda zai shafi bambancin zafin jiki.Saboda haka, ana iya amfani da lissafin naúrar yarda tashin hankali TA don bambanta da bel jimlar tashin hankali TW.Wannan sakamakon lissafin zai taimaka muku yin zaɓin zaɓin bel ɗin da ya dace kuma ya dace da buƙatun mai ɗaukar kaya.Da fatan za a koma zuwa Teburin FS da Teburin Ts a menu na hagu.

FORMULA: TA = BS X FS X FT

BS = Earfi mai karfin tenerile ƙarfi (kg / m)

FS da FT Suna Magana zuwa Tebur FS da Table FT

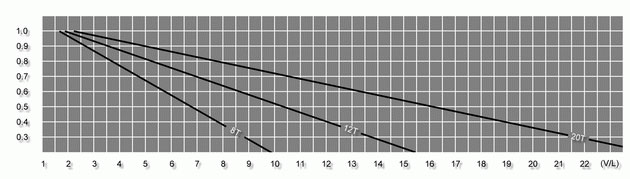

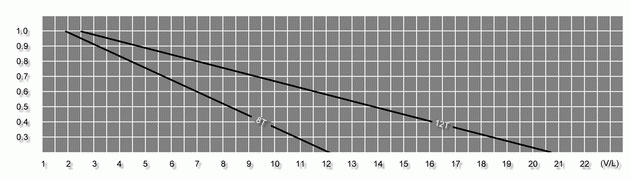

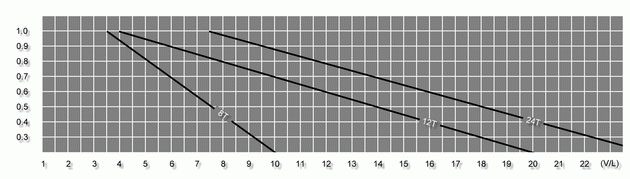

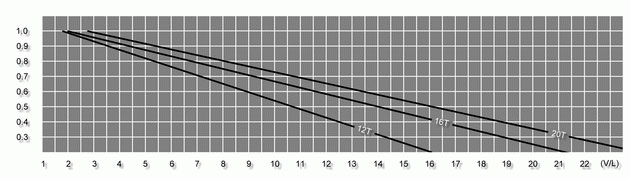

Table Fs

Saukewa: HS-100

Saukewa: HS-200

Saukewa: HS-300

Saukewa: HS-400

Saukewa: HS-500

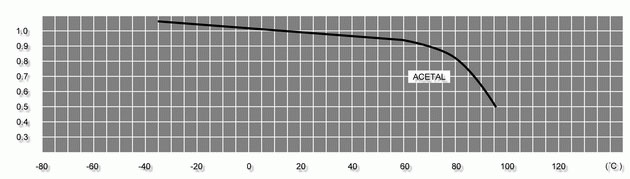

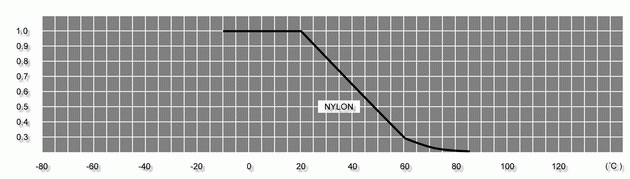

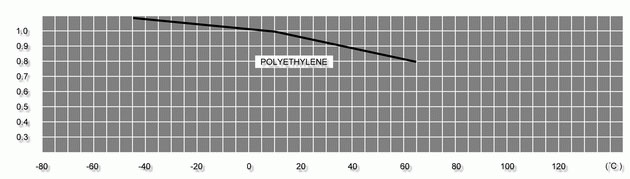

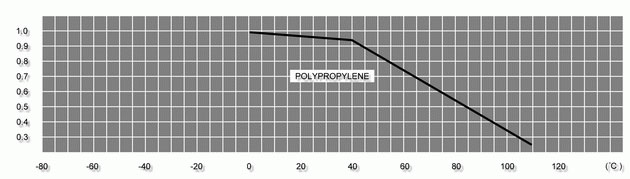

Table Ts

Acetal

Nailan

Polyethylene

Polypropylene

Zaɓin Shaft

FORMULA: SL = ( TW + SW ) ?BW

Teburin Nauyin Shafar Tuƙi / Idler - SW

| Girman Shaft | Nauyin Shaft (Kg/M) | |||

| Karfe Karfe | Bakin Karfe | Aluminum Alloy | ||

| Shafar square | 38mm ku | 11.33 | 11.48 | 3.94 |

| 50mm ku | 19.62 | 19.87 | 6.82 | |

| Zagaye Shaft | 30mm?/FONT> | 5.54 | 5.62 | 1.93 |

| 45mm?/FONT> | 12.48 | 12.64 | 4.34 | |

Juyawar Shaft / Idler - DS

Ba Matsakaici Ba

FORMULA :

DS = 5 ?10-4 ( SL ?SB3 / E ?/FONT> I)

Tare da Matsakaici Haɓaka

FORMULA :

DS = 1 ?10-4 ( SL ?SB3 / E ?I)

Nauni na Shaft ɗin Drive - E

| Naúrar: Kg/mm2 | |||

| Kayan abu | Bakin Karfe | Karfe Karfe | Aluminum Alloy |

| Matsakaicin Ƙarƙashin Ƙarƙashin Tuƙi | 19700 | 21100 | 7000 |

Lokacin Inertia - I

| Bore diamita na tuƙi sprocket | Lokacin inertia na shaft (mm4) | |

| Shafar Square | 38mm ku | 174817 |

| 50mm ku | 1352750 | |

| Zagaye Shaft | 30mm?/FONT> | 40791 |

| 45mm?/FONT> | 326741 | |

Ƙididdigar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwarar Drive Shaft Torque - TS

| FORMULA : | TS = TW ?BW?R |

Don ƙimar lissafin da ke sama, da fatan za a kwatanta da teburin da ke ƙasa don zaɓar mafi kyawun tuƙi.Idan karfin juzu'i na tuƙi yana da ƙarfi sosai, ana iya amfani da ƙaramin sprocket don rage ƙarfin wutar lantarki, da kuma tattalin arziƙin babban farashi na shaft da ɗaukar nauyi.

Yin amfani da ƙarami sprocket don dacewa da tuƙin tuƙi wanda ke da mafi girman diamita don rage juzu'i, ko yin amfani da mafi girman sprocket don dacewa da mashin tuƙi wanda ke da ƙaramin diamita don ƙara juzu'i.

Matsakaicin Factor Torque don Drive Shaft

| Torque | Kayan abu | Diamita na Jarida (mm) | ||||||

| 50 | 45 | 40 | 35 | 30 | 25 | 20 | ||

| Kg-mm x 1000 | Bakin Karfe | 180 | 135 | 90 | 68 | 45 | 28 | 12 |

| Karfe Karfe | 127 | 85 | 58 | 45 | 28 | 17 | 10 | |

| Aluminum Alloy | -- | -- | -- | 28 | 17 | 12 | 5 | |

Ƙarfin doki

Idan an zaɓi motar tuƙi don injin rage kayan aiki, ƙimar dawakai yakamata ya zama mafi girma fiye da samfuran ɗaukar kaya da jimillar ƙarfi da ke haifarwa yayin bel yana gudana.

Ƙarfin Doki (HP)

| FORMULA : | = 2.2 × 10-4 × TW × BW × V |

| = 2.2 × 10-4 (TS × V / R) | |

| = Watts × 0.00134 |

Watts

| FORMULA : | = ( TW × BW × V) / ( 6.12 × R) |

| = ( TS × V ) / ( 6.12 × R ) | |

| = HP × 745.7 |

Table FC

| Kayan aikin dogo | Zazzabi | FC | ||

| Belt Material | bushewa | Jika | ||

| HDPE / UHMW | -10°C ~ 80°C | PP | 0.10 | 0.10 |

| PE | 0.30 | 0.20 | ||

| Actel | 0.10 | 0.10 | ||

| Nailan | 0.35 | 0.25 | ||

| Acetal | -10°C ~ 100°C | PP | 0.10 | 0.10 |

| PE | 0.10 | 0.10 | ||

| Actel | 0.10 | 0.10 | ||

| Nailan | 0.20 | 0.20 | ||

Da fatan za a bambanta kayan dogo da kayan bel na mai jigilar kaya tare da tsarin jigilar kaya a bushe ko yanayin jika don samun ƙimar FC.

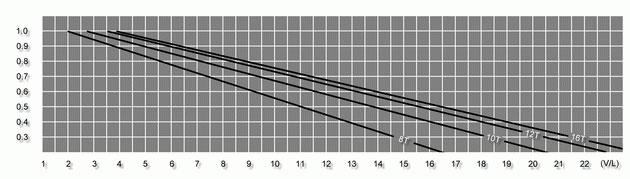

Ca, Cb darajar

| Kwangilar Juyawar belt | Ƙimar Ƙarfafawa Tsakanin Conveyor Belt Edge & Rail Strip | |||||

| FC ≤ 0.15 | FC ≤ 0.2 | FC ≤ 0.3 | ||||

| Ca | Cb | Ca | Cb | Ca | Cb | |

| ≥ 15 ° | 1.04 | 0.023 | 1.05 | 0.021 | 1.00 | 0.023 |

| ≥ 30 ° | 1.08 | 0.044 | 1.11 | 0.046 | 1.17 | 0.048 |

| ≥ 45 ° | 1.13 | 0.073 | 1.17 | 0.071 | 1.27 | 0.075 |

| ≥ 60 ° | 1.17 | 0.094 | 1.23 | 0.096 | 1.37 | 0.10 |

| ≥ 90 ° | 1.27 | 0.15 | 1.37 | 0.15 | 1.6 | 0.17 |

| ≥ 180 ° | 1.6 | 0.33 | 1.88 | 0.37 | 2.57 | 0.44 |

Bayan samun darajar FC daga Tebur FC, da fatan za a bambanta shi da kusurwar mai lanƙwasa, kuma zaku iya samun darajar Ca da ƙimar Cb.